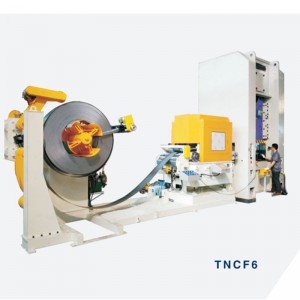

JNCF-series-3IN1 NC Servo Feeder Machine

Characteristic

1. Leveling adjustment adopts electronic digital display meter reading;

2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment;

3. The height of feeding line is adjusted by motor driven elevator;

4. A pair of hollow roller blocking device is used for material sheet;

5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment);

6. Hydraulic pressing arm device;

7. The gear motor drives the feeding head device of the pressing wheel;

8. Hydraulic automatic feeding head device;

9. Hydraulic support head device;

10. The feeding system is controlled by Mitsubishi PLC program;

11. The precision of feeding is controlled by Yaskawa servo motor and high precision planetary servo reducer;

Speclflcations:3in1 servo straighter feeder w/uncoiler

| Name | JNCF1 -200 | JNCF1 -300 | JNCF1 -400 | JNCF2 -300 | JNCF2 -400 | JNCF2 -500 | JNCF2 -600 | JNCF3 -300 | JNCF3 -400 | JNCF3 -500 | JNCF3 -600 | JNCF4 -300 | JNCF4 -400 | JNCF4 -500 | JNCF4 -600 |

| Width of material(mm) | 75-200 | 75-300 | 75-400 | 75-300 | 75-400 | 75-500 | 75-600 | 75-300 | 75-400 | 75-500 | 75-600 | 75-300 | 73-400 | 75-500 | 75-600 |

| Thickness of material(mm) | 0.1-1.0 | 0.3~2.3 | 0.4~3.2 | 0.54~4.5 | |||||||||||

| Coil weight(kgs) | 1.2T(Customizable) | 2T(Customizable) | 3T(Customizable) | 2T(Customizable) | 3T(Customizable) | 2T(Customizable) | 3T(Customizable) | ||||||||

| Coil I.D(mm) | 508 | 508 | 508 | 508 | |||||||||||

| Coil OD.(mm) | 1200 | 1200 | 1200 | 1200 | |||||||||||

| Max.Speed(m/min) | 16 | 16 | 16 | 16 | |||||||||||

| Feed pitch Accuacy(mm) | ±0.15 | ±0.15 | ±0.15 | ±0.15 | |||||||||||

| Feed Roll | upper1 / lower1 | upper1 / lower1 | upper1 / lower1 | upper1 / lower1 | |||||||||||

| Work Roll | upper5/ lower4 | upper5/ lower4 | upper5/ lower4 or upper4/ lower5 | upper5/ lower4 | |||||||||||

| Voltage | 380VAC/60Hz | 380VAC/60Hz | 380VAC/60Hz | 380VAC/60Hz | |||||||||||

| Air power supply | 5kg/cm² | 5kg/cm² | 5kg/cm² | 5kg/cm² | |||||||||||

| Uncoiler Expansion | By hand | By hand | By hand | By hand | |||||||||||

| Servo Motor(kw) | AC1.8KW(Equipped with servo reducer) | AC1.8KW(Equipped with servo reducer) | AC2.9KW(Equipped with servo reducer) | AC1.8KW(Equipped with servo reducer) | AC2.9KW(Equipped with servo reducer) | AC2.9KW(Equipped with servo reducer) | AC4.4KW | ||||||||

| Uncoiler Motor(kw) | 0.75KW 1.5KW | 1.5KW | 1.5KW | 1.5KW | |||||||||||

| Uncoil Height | ±60mm | ±60mm | ±60mm | ±60mm | |||||||||||

What are the benefits of using the three in one servo feeder?

The three in one feeder combines the functions of material rack, leveling machine and NC feeder, greatly reducing the area occupied by the previous feeding device. The CNC three in one servo feeding rack automatic detection equipment is equipped with feeding machine, and various conditions in operation can be automatically monitored, which has a great impact on reducing the product defect rate. At the same time, it also saves the labor cost of many enterprises.

The operation of the auxiliary devices of the three in one feeder is powered by air or electricity. The operation is simple and the maintenance is easy. After debugging, the failure rate is low, the leveling is relaxed and the feeding accuracy is high. In addition to these advantages, three in one feeder is more and more widely used, and it is more and more popular.

The three in one servo feeder has many advantages:

1. Feed line height recovery turbine adjustment device (electric, manual selection), convenient to meet the production of different products and mold adjustment, feed line height easy to change working standards

2. The discharging guide frame device enables the rear leveling material to stably and directly enter into the work of the mold. (mobile device)

3. The electric motor drives the pressure arm, and the three in one feeder acts on the uncoiling process of the plate, which increases the auxiliary transmission capacity of the material and makes the book more smooth.

4. Feeding roller and bearing steel roller calibration (SUJ2), high frequency heat treatment hrc60o after hard chromium plating, grinding, high hardness, wear resistance, long service life.