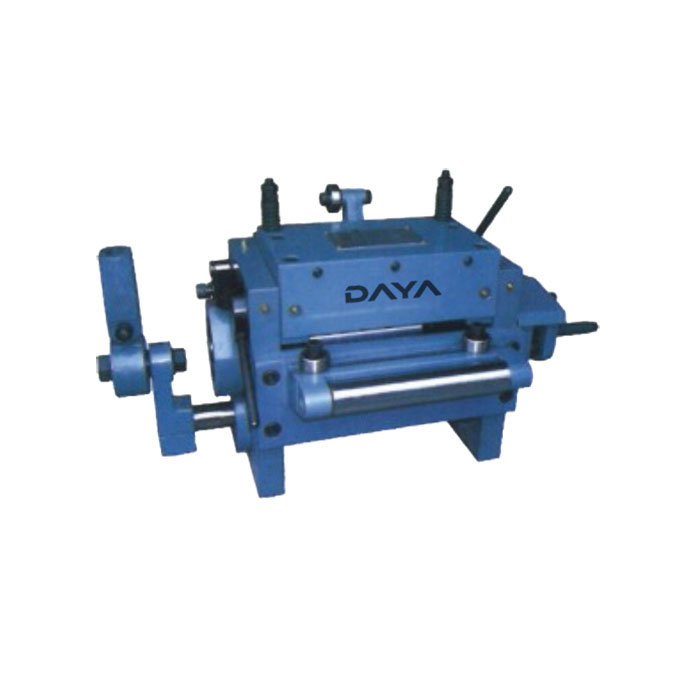

OEM manufacturer 25t Servo Press - SAF-A-series Servo Feeder Machine – Daya

OEM manufacturer 25t Servo Press - SAF-A-series Servo Feeder Machine – Daya Detail:

Characteristic

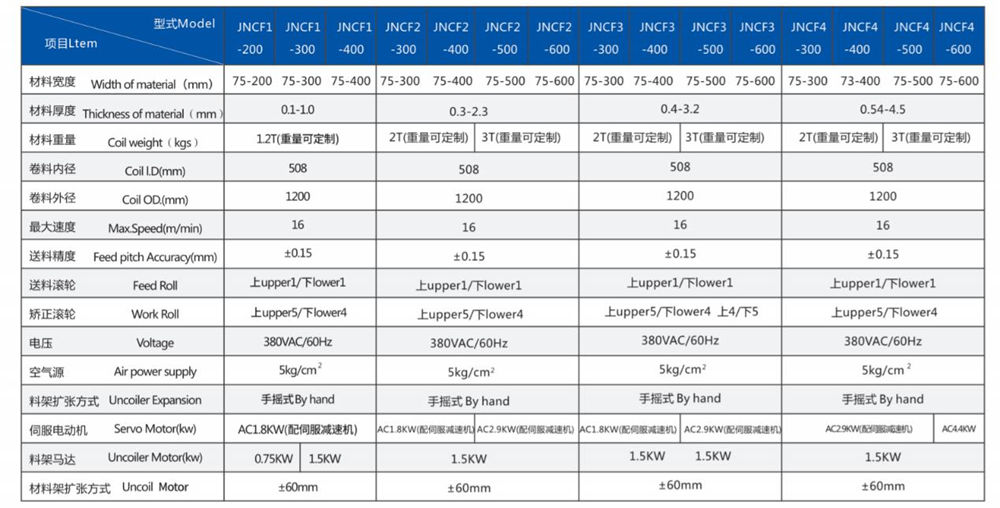

1. Leveling adjustment adopts electronic digital display meter reading;

2. High precision screw is driven by positive and negative two-way handwheel to control width adjustment;

3. The height of feeding line is adjusted by motor driven elevator;

4. A pair of hollow roller blocking device is used for material sheet;

5. Feeding roller and correction roller are made of high alloy bearing steel (hard chromium plating treatment);

6. Hydraulic pressing arm device;

7. The gear motor drives the feeding head device of the pressing wheel;

8. Hydraulic automatic feeding head device;

9. Hydraulic support head device;

10. The feeding system is controlled by Mitsubishi PLC program;

11. The precision of feeding is controlled by Yaskawa servo motor and high precision planetary servo reducer;

What is the function, purpose and application of servo feeder?

Servo feeder is a kind of equipment controlled by servo system, which is driven by motor and applied to steel coil, so that the material can be continuously, accurately and stably fed to punch or punch machine. It is also a kind of punching machine feeder, adding servo control system, making operation and use more convenient. The principle of servo feeder is not complicated as we mentioned before, and it is also a kind of peripheral equipment of punch.

Function of servo feeder: in the operation and production of punch, it can replace manual feeding action of punch, and has continuity, and the precision is more stable than manual operation. The AC servo control system is used to make the equipment high speed and high precision. The feeding accuracy can reach about ± 0.1 mm, and the cumulative error can be avoided. At the same time, high precision can be achieved in raw material production, forming, punching and cold bending, and the error is very small!. In addition, like the three in one servo feeder, it has the functions of opening, leveling and feeding, as well as automatic loading and unloading and feeding functions. The servo offset feeder has the function of left and right movement, which can realize the left and right moving feeding. For circular products, the reasonable arrangement can effectively reduce the waste of raw materials.

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for OEM manufacturer 25t Servo Press - SAF-A-series Servo Feeder Machine – Daya , The product will supply to all over the world, such as: Ukraine, Maldives, Accra, To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!