Special Design for Straight Side Single Point Press Machine - Straight Side Five Circle Guide Column Press (HS series) – Daya

Special Design for Straight Side Single Point Press Machine - Straight Side Five Circle Guide Column Press (HS series) – Daya Detail:

Performance characteristics

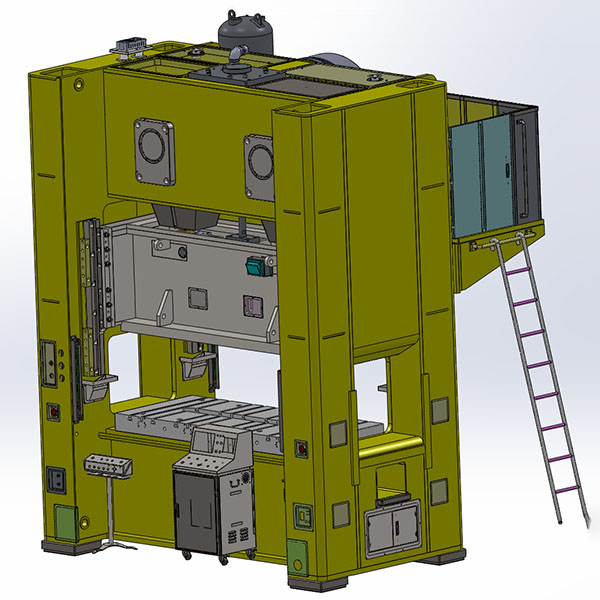

1. The frame is made of high strength cast iron and high-precision integrated gantry structure, which prevents the opening problem of the fuselage under load, and realizes the processing of high-precision products;

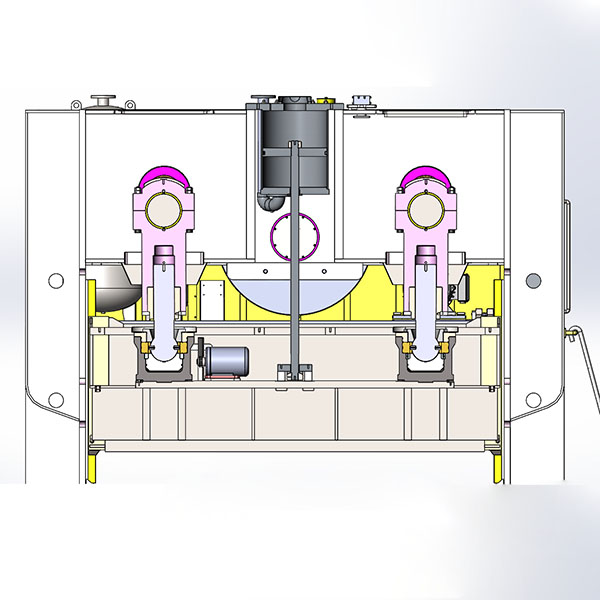

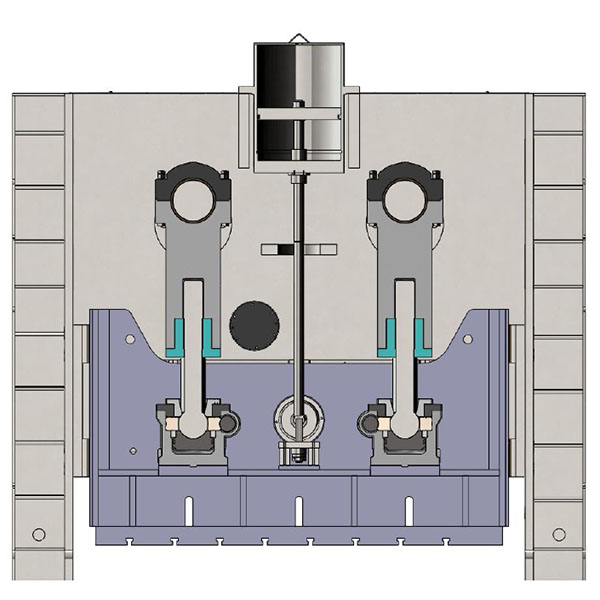

2. Double axis center guide, four guide pillars guide the whole length, so even eccentric load can maintain excellent stamping accuracy and prolong the life of punch;

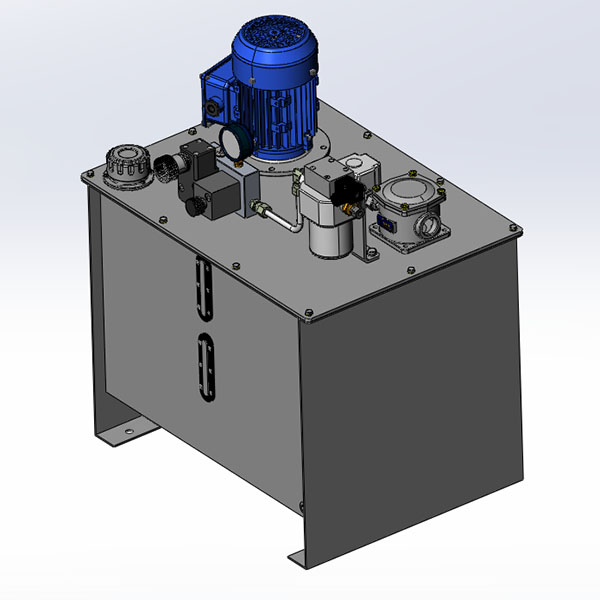

3. The forced lubrication and oil supply system of oil cooler are used to minimize the thermal deformation, which can be used for high-precision product processing;

4. Excellent dynamic balance device can reduce vibration and make the punch have the best precision and stability;

5. Specially equipped with electric mold adjusting function and mold height indicator to facilitate mold height adjustment;

6. The hydraulic sliding block locking system keeps the die height unchanged to ensure the product requirements;

7. Man machine interface microcomputer control, numerical fault monitoring system screen display, easy to operate;

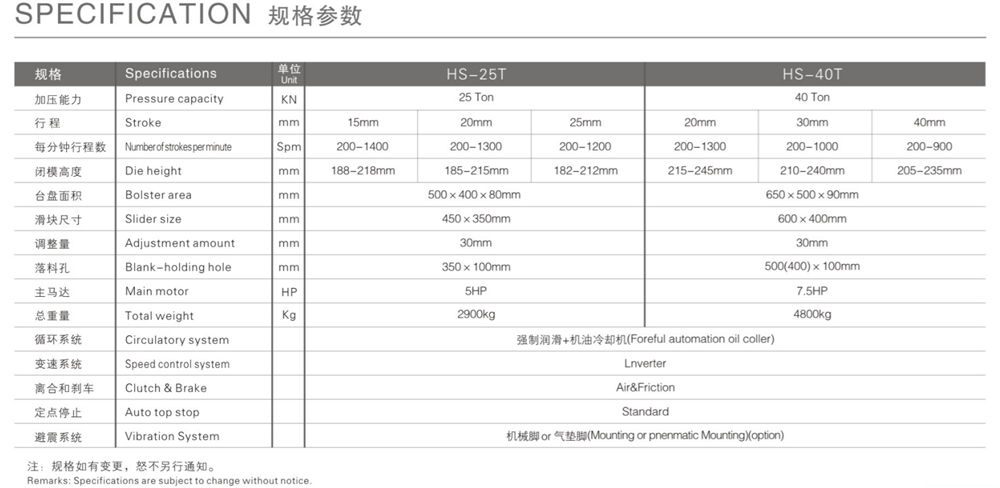

Specification

DAYA straight side double crank punch press

VS

Other straight side double crank presses

Daya press

Daya press: with platform and safety fence, convenient for clutch maintenance and change of cooling oil, main motor belt is loose and easy to adjust, and convenient for subsequent maintenance. Safer and more convenient.

Other press

Other press: Without maintenance platform. Clutch maintenance, replacement of cooling oil, loose adjustment of main motor belt, etc. which can only be completed with the assistance of forklift, which is not convenient for subsequent repair and maintenance. There are some potential safety hazards.

Daya press

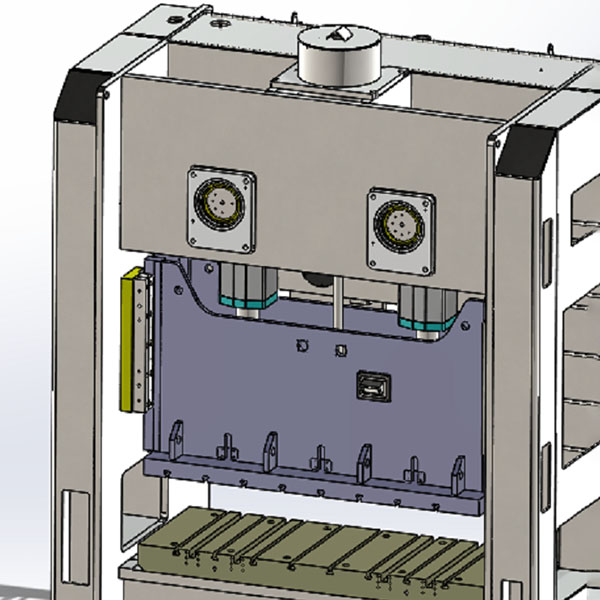

Daya press: Daya press adopts four corners and eight sides to surround the guide rail. In the stamping forming position, the slide guide rail is included by all the guide rails on the table body. This kind of guide rail has the characteristics of high stamping accuracy, strong anti eccentric load capacity, small rail wear and long precision retention time.

Other press

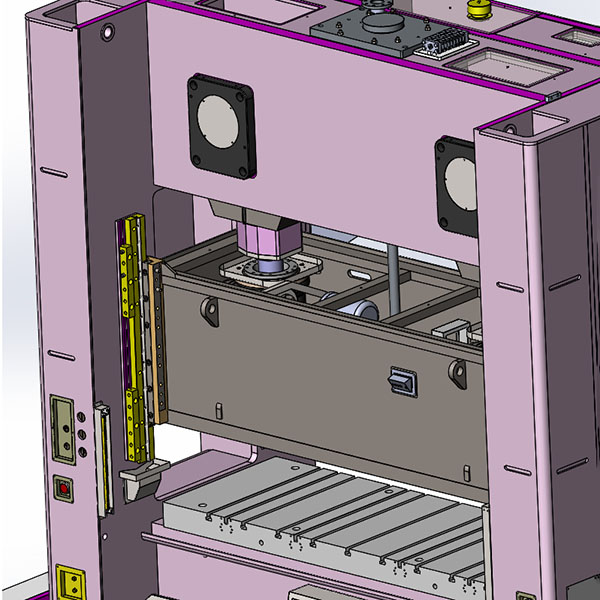

Other press: the guide rail with semi enclosed structure as shown in the right figure is adopted. During the stamping process, there is a section of guide rail exposed. During the stamping process, the slide guide rail is easy to tilt, with poor anti bias load capacity, large rail wear, short precision retention time and high maintenance cost.

Daya press

Daya press: the distance between the two points of force application is more than 60%; Advantages: the larger the distance between the two force application points, the greater the eccentric bearing capacity; the larger the distance between the two force application points, the higher the design cost.

Other press

Other press: the distance between the two points is generally less than 50%; Disadvantages: the smaller the distance between the two force application points, the smaller the eccentric bearing capacity. The guide rail is easy to tilt, the guide way is easy to wear, and the precision of guide rail is poor.

Daya press

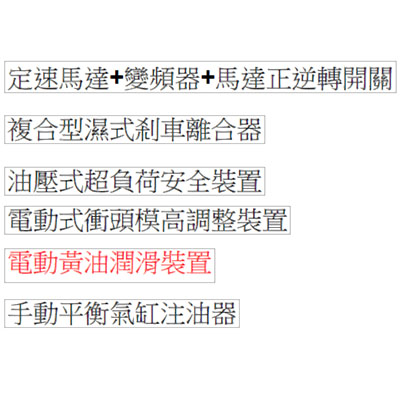

Daya press: forced thin oil circulation system, energy saving, can be recycled, fan thermal performance is good, compared with grease lubrication can be increased by 5-10 beats per minute.

Other press

Other press: electric grease pump, grease can not be reused, no advantage of forced thin oil circulation system.

Daya press

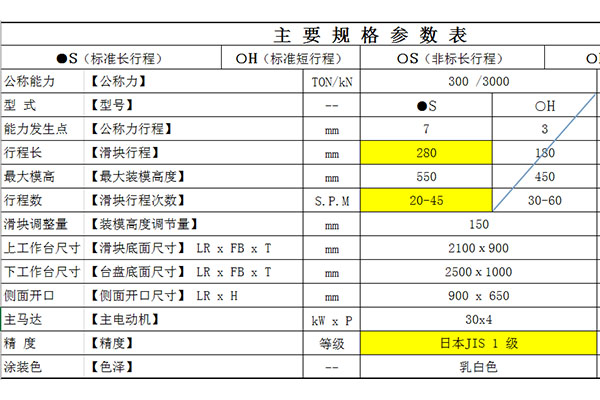

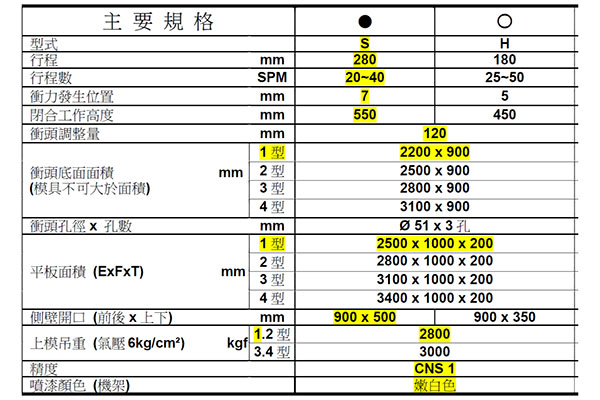

Daya press: when the stroke length is the same, the forced thin oil circulation system has higher efficiency, compared with grease lubrication, it can increase 5-10 beats per minute. Strictly follow the Japanese JIS level 1 standard; the Japanese JIS level 1 standard is higher than the Taiwan CNS level 1 standard.

Other press

Other press:electric grease pump, grease can not be reused, no forced oil circulation system advantages. according to Taiwan CNS level 1 standard

Slide guide of Daya punch press

VS

other slide guides of punch

Daya press

Other press

Guide rail of Daya punch press

1.High frequency quenching process: hardness above hrc48;

2. Grinding process of guide rail: the surface finish can reach ra0.4-ra0.8 (mirror surface), flatness, parallelism and verticality within 0.005mm/ ㎡.

3.The machine tool has the advantages of small wear, high precision, long precision maintenance time, long service life and low energy consumption.

Other press guide railno quenching process; milling processing, surface roughness ra1.6-ra3.2, flatness, parallelism, perpendicularity more than 0.3mm / ㎡

Daya press crankshaft

VS

other press crankshafts

Daya punch press: the crankshaft is made of high strength alloy 42CrMo Advantages: the strength is 1.3 times higher than that of 45 steel, the service life is long, the wear resistance is good, the wear is small, and the precision is maintained for a long time.

Other presses: made of 45 steel, Disadvantages: low cost,the strength and wear resistance are not comparable to 42CrMo

Daya

Oil way of DAYA punch PRESS: Φ 8 is used for oil pressure lubrication piping.

Advantages: long pipeline, large diameter is not easy to block, break, ensure the safety of lubricating oil, smooth.

Other

Other presses: the oil pressure lubrication piping of press adopts Φ 6.

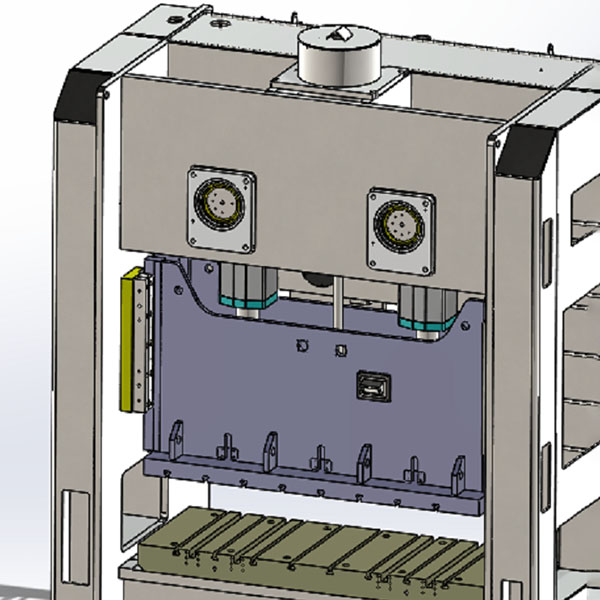

Product detail pictures:

Related Product Guide:

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and development, we will build a prosperous future together with your esteemed company for Special Design for Straight Side Single Point Press Machine - Straight Side Five Circle Guide Column Press (HS series) – Daya , The product will supply to all over the world, such as: United Kingdom, Guyana, Lahore, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.