110 Ton C Frame Double Point Crank Precision Press

(Mechanical Feeding Shaft Is Reserved At The Front End)

1 Equipment model, name and quantity:

|

Equipment model |

Name |

Quantity |

Note |

|

STC-110 |

C frame single point crank precision press |

1 |

Mechanical feed shaft is reserved at the front of the press |

2 Energy and environmental requirements

⑴ Power supply voltage: 380V±10%, three-phase five-wire

⑵ Air pressure: pressure 0.6 ~ 0.8mpa

⑶ Operating temperature: -10℃ ~ 50℃

⑷ Working humidity: ≤ 85%

3 Equipment implementation standard

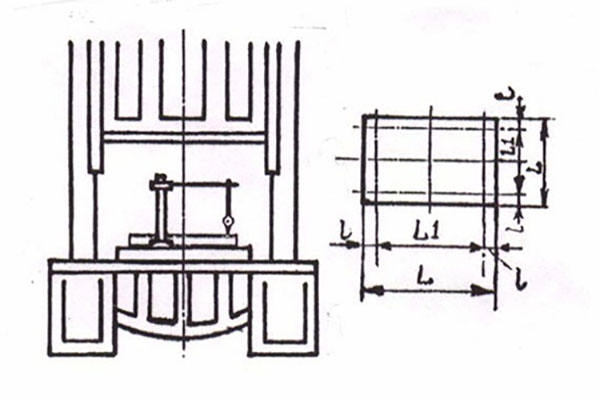

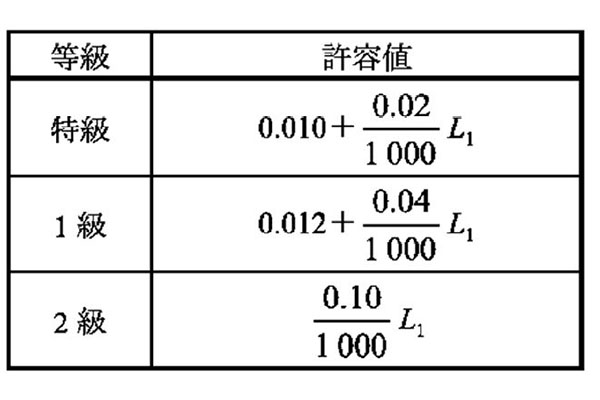

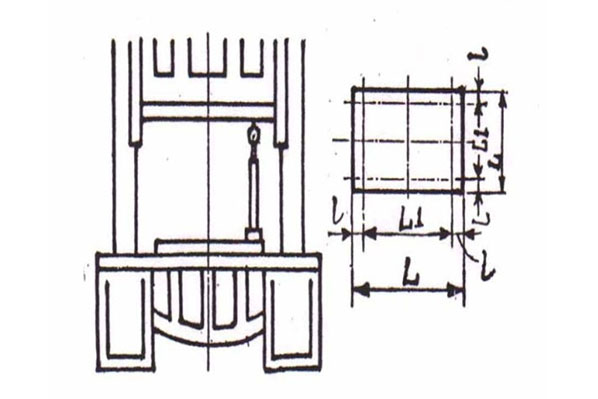

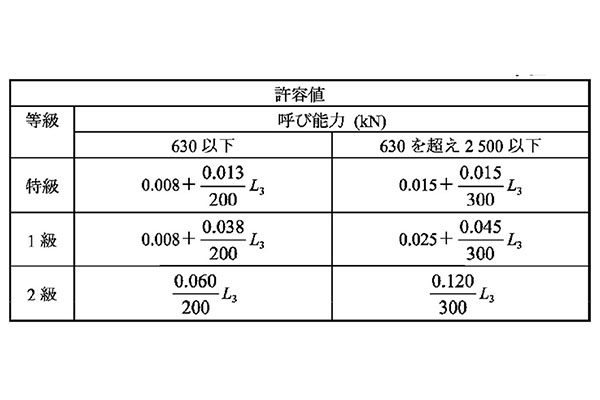

⑴ GB/T 10924-2009 《Accuracy of straight side mechanical press》

⑵ GB/T5226.1-2002 《General technical requirements for industrial machinery and electrical equipment》

⑶ GB5226.1—2002 《Mechanical safety mechanical electrical equipment - part I general technical conditions》

⑷ JB/T1829—1997 《General technical conditions of forging press》

⑸ GB17120-1997 《Safety and technical conditions of forging machinery》

⑹ JB/T9964—1999 《Technical requirements of straight side mechanical press》

⑺ JB/T8609-1997 《Welding technical conditions of forging press》

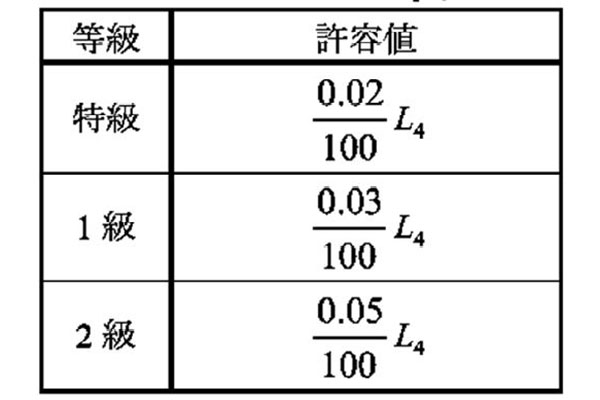

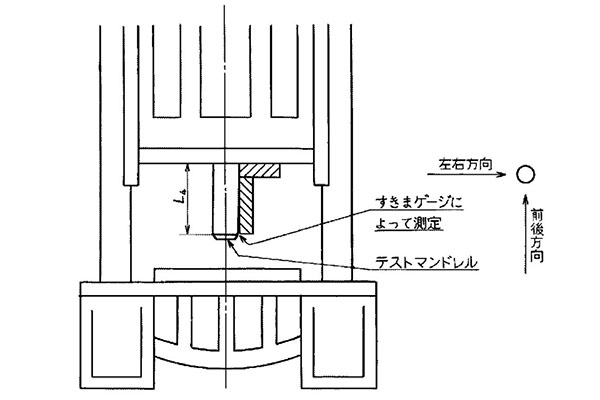

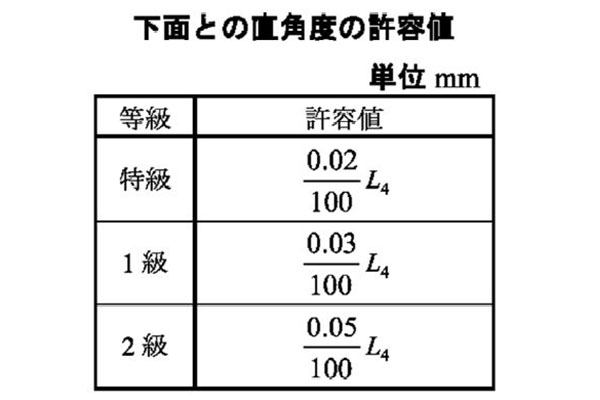

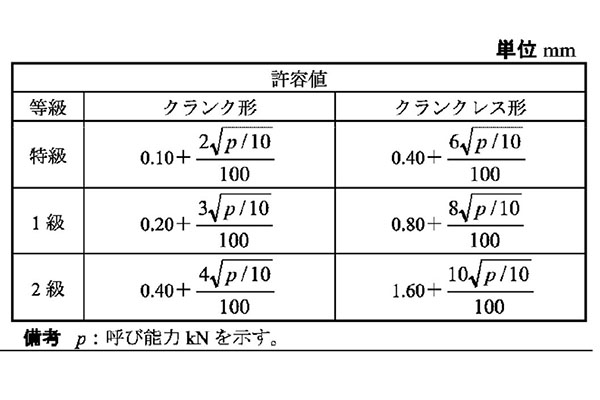

3.1 The equipment is in accordance with Japanese JIS level 1 precision inspection standard:

4 Main equipment parameters

|

Number |

Item |

Unit |

STC-110(V) |

|

1 |

Transmission type |

—— |

Crankshaft, |

|

2 |

Body type |

—— |

Integral steel plate welding |

|

3 |

Nominal capacity |

Kn/Ton |

1100/110 |

|

4 |

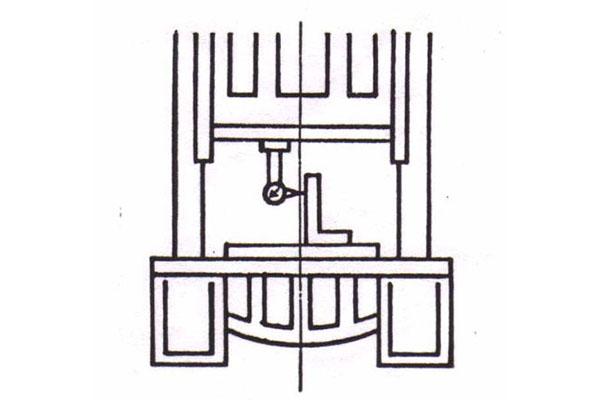

Slide guide bit structure |

--- |

Two points and six paths |

|

5 |

Ability point |

mm |

5 |

|

6 |

Applying points |

point |

2 |

|

7 |

Slider travel length |

mm |

180 |

|

8 |

Maximum modulus height |

mm |

400 |

|

9 |

Slider adjustment |

mm |

100 |

|

10 |

Continuous trips per minute |

Times/Min |

35-65 |

|

11 |

Size of upper workbench (left and right x before and after) |

mm |

1400 x 500 |

|

12 |

Size of lower workbench (left and right x before and after) |

mm |

1800 x 650 |

|

13 |

Main motor power + frequency converter |

kW x P |

11 x 4 + Frequency converter |

|

14 |

Air source pressure |

MPa |

0.6 |

|

15 |

The color of the press |

color |

White |

|

16 |

Precision grade |

Grade |

Japan JIS level 1 |

5. The technical requirements

5.1 Main structural features and methods

(1) High frequency quenching of slide guide, hardness above HRC45 degrees,

Advantages: wear resistance greatly improved. (no high-frequency quenching treatment in other manufacturers)

(2) Slider guide rail professional grinding processing, surface roughness between Ra0.4-Ra0.8,

Advantages: maintain high precision, wear greatly reduced. (no quenching and grinding processing by other manufacturers)

(3) Slide rail plane 0.01mm/M, high precision.

Advantages: the accuracy is greatly improved. (other manufacturers above 0.03mm/M)

(4) All our gas circuit components are Japanese SMC.

(5) We use the American MAC brand jet electromagnetic valve, jet response sensitivity is high.

(6) The material of crankshaft is 42CrMo (Same material as AIDA).

Advantages: 30% stronger than 45 steel, longer service life. (generally 45 steel from other manufacturers)

(7) The copper sleeve is zqsn10-1 (tin-phosphorous bronze), which is similar to AIDA copper sleeve.

Other manufacturers use BC6 (colliers brass is also called 663 copper), which is 50% stronger than ordinary copper (surface pressure) and more durable and durable. Longer accuracy and longer service life.

(8) We all piping is Φ 6, oil flow, not easy jam. (other factories usually use Φ 4).

(9) The tee is made of Japanese brand TM-3 sintered copper alloy (same material as AIDA)

Advantage: the chance that bites dead greatly reduces (general manufacturer is cast iron).

◆ Environmental impact

This product has no adverse effect on the environment and will not produce harmful gas.

◆ Handling and installation

⑴ Transport and storage of equipment:

① The equipment adopts appropriate anti-rust, anti-vibration and anti-impact measures in the packaging process, which can guarantee the transportation and storage of 5 °c ~ 45° c.

② When the equipment is transported and stored, attention should be paid to it. The equipment and outer packing should not be directly exposed to rain or water, and the outer packing should not be damaged.

⑵Lifting of equipment:

When lifting and unloading by crane, the bottom or side of the product shall not be subjected to shock or strong vibration.

⑶ The installation:

Remove and clean the plastic film wrapped on the outside, remove the plug, and install PU1 pipe connector and PU pipe, the length of PU pipe is about 700mm.

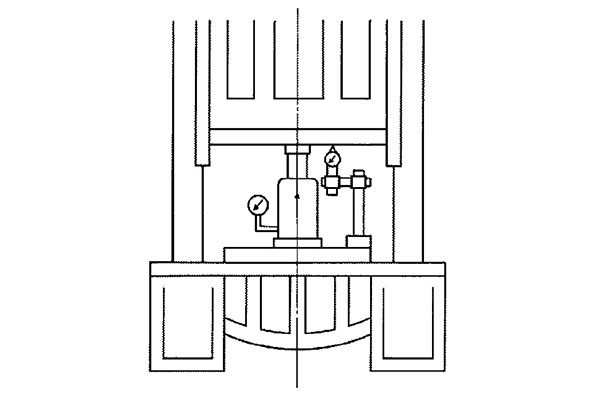

5.2 Main component structure

⑴ Mechanical parts

The frame is welded with Q235B material. After welding, tempering is carried out to eliminate the internal stress of the material. Fuselage guide rail position with two corners of six guide road.

⑵ Transmission type

The transmission gear, crankshaft and connecting rod are assembled on the upper part of the press. The main motor is installed on the rear measuring surface of the frame, flywheel, clutch, etc

In the position of the rear side of the frame, the flywheel has been tested for balance before assembly.

The gear part adopts straight tooth transmission mechanism, and its material is made of high-strength alloy steel 42CrMo, and the corresponding heat treatment is carried out.

Dry low inertia clutch/brake. The clutch/brake control system is equipped with an abnormal detection device.

All shafts receiving are made of tin-phosphorous bronze wear-resistant material.

⑶ The slider

The slider is made of HT250 material. The guide adopts two-point six-side rectangular guide,

The bottom surface of the slide block and the top surface of the table have T-groove, which is used to install the mould. The height of sliding block is adjusted by electric motor over 80 tons (including).

Adopt hydraulic automatic overload protection system.

⑷Lubrication system

The press is lubricated with electric butter and equipped with low oil level alarm system, so it is safe and reliable. The equalizer is: manual butter feeding pump.

⑸ Balancing device system

Adopt air pressure type slide block balance device, Air pressure can be controlled at the air pressure regulating valve.

⑹ Electrical part

The electrical equipment is controlled by PLC, equipped with powerful human-machine interface, and displayed by the touch screen of famous brands.

Placed on the main operation panel, the following functions can be achieved:

① The touch screen displays Chinese characters (or switch between Chinese and English), which is simple and easy to understand, and displays various data parameters of the press, such as the number of strokes, electronic CAM Angle, etc.And the corresponding data can be set through the touch screen;

② Display the working flow of the press, so that the operator can operate the press more easily,and has the main flow state indication;

③ Operation and failure information display, so that operators and maintainers more quickly to solve the press problems, reduce the downtime;

④ PLC input/output point real-time monitoring function;

⑤ Set the product count screen, which can display the current product count in real time, and set the target number of work pieces.

⑥ Electric control press adopts three-phase power supply, 380V,50Hz.

⑦ The main motor is equipped with thermal overload and zero speed anti-reversal protection.

⑧ The realization of each function of punch control has corresponding safety chain. The panel is equipped with fault indicator light and reset button to complete the function of reset after fault confirmation.

5.3 Mode of operation

Press set inching, single, continuous three operating modes. The working mode is selected by the switch and centrally controlled by the button.

5.4 Safety measures

⑴ Emergency stop button: press "emergency stop" button in case of abnormal operation of press. The press has three emergency stop buttons.

One on the operation control panel, one on the column, one on the two-handed operation table; Press any of the emergency stop buttons and the press will stop immediately. The position of the emergency stop button on the column is about 1.2 meters from the ground, which meets the requirements of ergonomics;

⑵ Two-hand operation button: two-hand downward synchronization time limit is 0.2-0.5s;

⑶ Overload protection: the slide block is equipped with hydraulic overload protection system to ensure that the press will not damage the press and die due to overload.

Overload after the slider that stays at the bottom dead point, can only use inching, reverse return to the top dead point for readjustment and pressure, work.

6. Configuration of equipment

6.1 Main structural part

|

Serial number |

Part Name |

model |

Materials, treatment methods |

|

1 |

Machine frame |

Basic piece |

Materials Q235B |

|

2 |

Workbench |

Basic piece |

Materials Q235B |

|

3 |

Crankshaft |

Basic piece |

Materials 42CrMo, quenched and tempered Hs42±20 |

|

4 |

flywheel |

Basic piece |

Materials HT-250 |

|

5 |

Slider |

Basic piece |

Materials HT-250 |

|

6 |

Cylinder |

Basic piece |

Materials 45 |

|

7 |

Worm gear |

Basic piece |

Materials ZQSn10-1 Tin phosphor bronze |

|

8 |

Worm |

Basic piece |

Materials 40Cr, quenched and tempered Hs40±20 |

|

9 |

link |

Basic piece |

Materials QT-500 Blunting treatment |

|

10 |

Sawtooth ball head |

Basic piece |

Materials 40Cr, quenched and tempered Hs40±20 |

|

11 |

Slider guide |

Basic piece |

Materials HT-250, High frequency quenching hrc45 degrees above |

|

12 |

Copper (copper sleeve) |

Basic piece |

Materials ZQSn10-1 Tin phosphor bronze |

6.2 Main parts manufacturer/brand

|

Nunber |

Part Name |

Manufacturer/brand |

|

1 |

Main motor |

Siemens |

|

2 |

Slider adjustment motor |

SANMEN |

|

3 |

PLC |

Japan Omron |

|

4 |

AC contactor |

France Schneider |

|

5 |

Intermediate relay |

Japan Omron |

|

6 |

Dry clutch brake |

Italy OMPI |

|

7 |

Double solenoid valve |

USA ROSS |

|

8 |

Thermal relay, auxiliary connector |

France Schneider |

|

9 |

control button |

France Schneider |

|

10 |

Air filtration |

Japan SMC |

|

11 |

Oil mister |

Japan SMC |

|

12 |

Pressure reducing valve |

Japan SMC |

|

13 |

Hydraulic overload pump |

Japan,Showa |

|

14 |

Two-hand button |

Japan Fuji |

|

15 |

Electric oil pump |

Japan IHI |

|

16 |

Main bearing |

USA Timken /TWB |

|

17 |

Anti-vibration foot |

Hengrun |

|

18 |

air switch |

France Schneider |

|

19 |

Frequency converter |

ZHENGXIAN |

|

20 |

touch screen |

Kunlun Tongtai |

|

21 |

Seals |

Taiwan SOG |

|

22 |

Preset counter |

Japan Omron |

|

23 |

Multi-section switch |

Siemens, Germany |

|

24 |

Air blowing device |

USA MAC |

|

25 |

Mold die illumination |

Puju LED |

|

26 |

Misfeed detection interface reserved |

Wiring through PLC |

|

27 |

Photoelectric protection device |

LAIEN |

6.3 Accessories, special tools list

|

Number |

item name |

Type of goods |

Quantity |

Optional / standard |

|

1 |

Maintenance tools and toolbox |

accessories |

1 set |

standard |

6.4 Special equipment (for options) list

|

Number |

name |

Brand |

Optional / standard |

|

1 |

2-channel tonnage |

Japan Rikenji |

Optional |

|

2 |

Misfeed detection device |

Japan Rikenji |

Optional |

|

3 |

Bottom dead point detection device |

Japan Rikenji |

Optional |

|

4 |

Rapid mold changing device |

Taiwan Fuwei |

Optional |

|

5 |

Feeder machine |

Taiwan TUOCHENG |

Optional |

|

6 |

Die pad (air cushion) |

self made |

Optional |

|

7 |

Feeding group |

self made |

Optional |