Top Quality 25kg Four Axis Transfer Robot - Welding Robot Series – Daya

Top Quality 25kg Four Axis Transfer Robot - Welding Robot Series – Daya Detail:

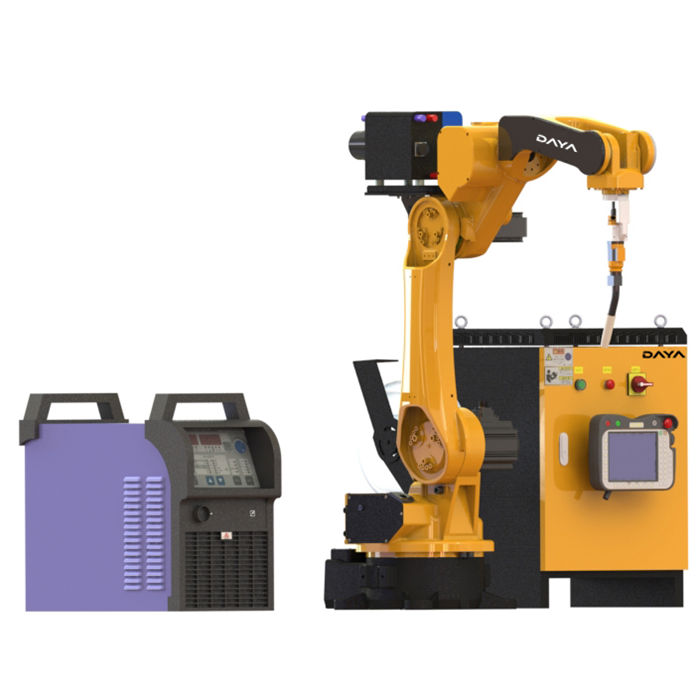

Welding robot

Welding robot series JZJ06C-180

Welding robot series JZJ06C-144

Welding robot series JZJ06C-160

Welding robot series JZJ06C-200

Brief introduction

Welding robot is an industrial robot engaged in welding (including cutting and spraying). According to the definition of international organization for Standardization (ISO) that industrial robot belongs to standard welding robot, industrial robot is a multi-purpose, repeatable programmable manipulator with three or more programmable axes, which is used in the field of industrial automation. In order to adapt to different applications, the mechanical interface of the last axis of the robot is usually a connecting flange, which can be connected with different tools or end effectors. Welding robot is to install welding tongs or welding (cutting) gun on the end shaft flange of industrial robot, so that it can carry out welding, cutting or thermal spraying.

Robot welding is the use of mechanized programmable tools (robots), which completely automate a welding process by both performing the weld and handling the part. Processes such as gas metal arc welding, while often automated, are not necessarily equivalent to robot welding, since a human operator sometimes prepares the materials to be welded. Robot welding is commonly used for resistance spot welding and arc welding in high production applications, such as the automotive industry.

Robot welding is a relatively new application of robotics, even though robots were first introduced into US industry during the 1960s. The use of robots in welding did not take off until the 1980s, when the automotive industry began using robots extensively for spot welding. Since then, both the number of robots used in industry and the number of their applications has grown greatly. In 2005, more than 120,000 robots were in use in North American industry, about half of them for welding.[1] Growth is primarily limited by high equipment costs, and the resulting restriction to high-production applications.

Robot arc welding has begun growing quickly just recently, and already it commands about 20% of industrial robot applications. The major components of arc welding robots are the manipulator or the mechanical unit and the controller, which acts as the robot’s “brain”. The manipulator is what makes the robot move, and the design of these systems can be categorized into several common types, such as SCARA and cartesian coordinate robot, which use different coordinate systems to direct the arms of the machine.

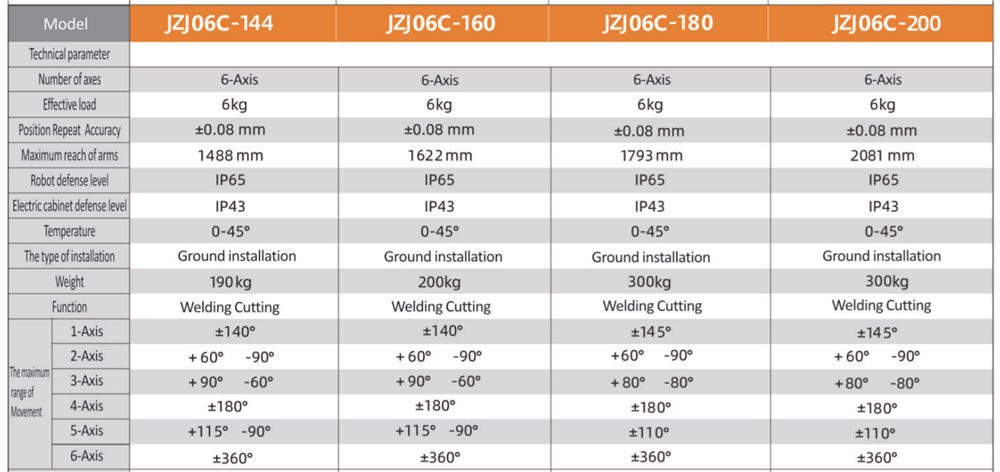

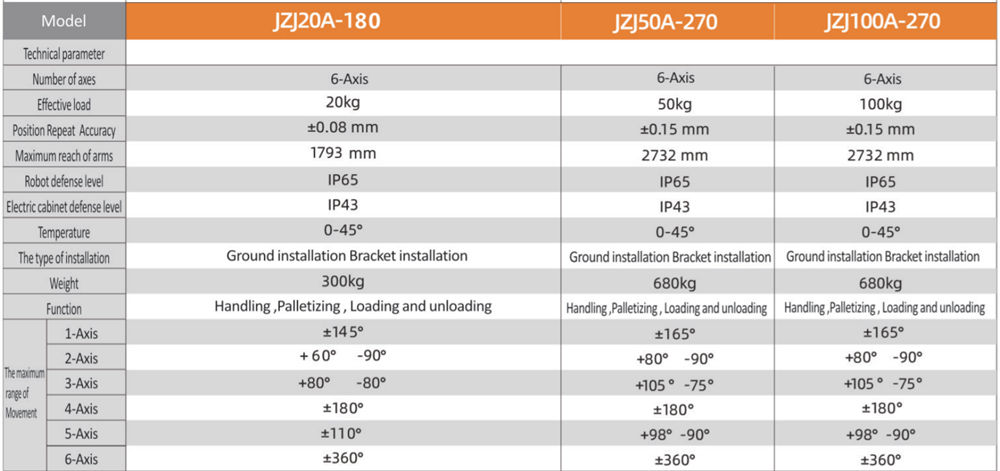

Welding Robot Series Technical Parameters

Product detail pictures:

Related Product Guide:

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for Top Quality 25kg Four Axis Transfer Robot - Welding Robot Series – Daya , The product will supply to all over the world, such as: Eindhoven, Paraguay, Denver, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.